Read more about Silestone Quartz Kitchen Worktops here >

DEEPER DOWNTURNS

For a chunkier looking Silestone® Quartz Worktop, the very latest in manufacturing technology enables us to offer a 20mm worktop with a downturn of 40-100mm. Silestone® Quartz worktops with the deeper downturn are only available in straight runs, with a single bevel edge detail. Please contact our sales office for further details.

Quotes includes double bevel edge detail,

Slab Size

Typical slab size 3000 x 1400mm. Any sizes over this would need a join.

Joins

Silestone® Quartz joints are finished with a small ariss to the top edge. Silicone sealant is applied to prevent water ingression.

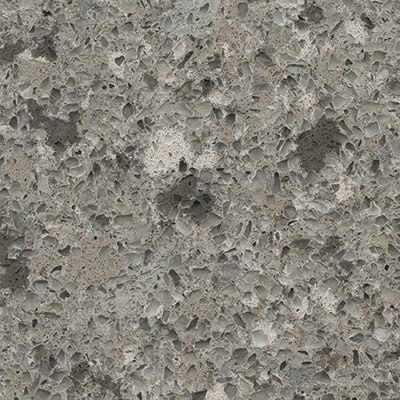

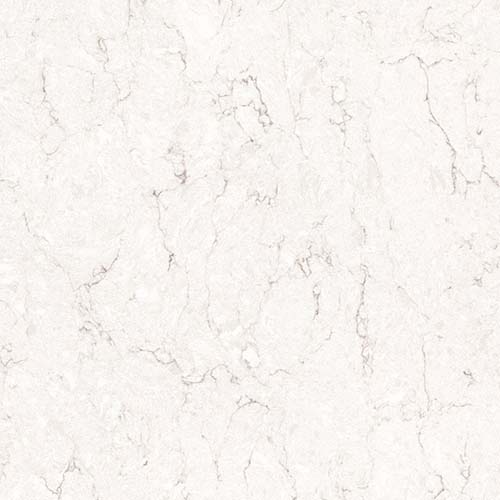

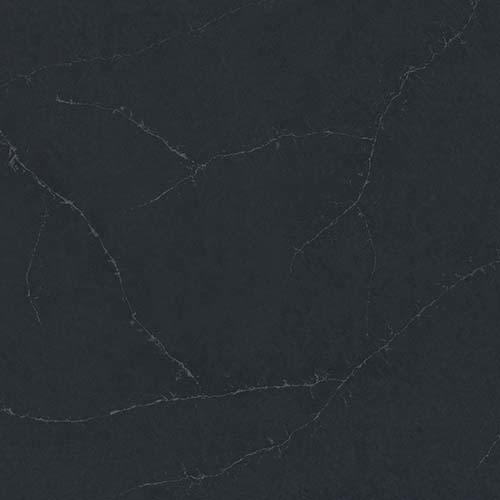

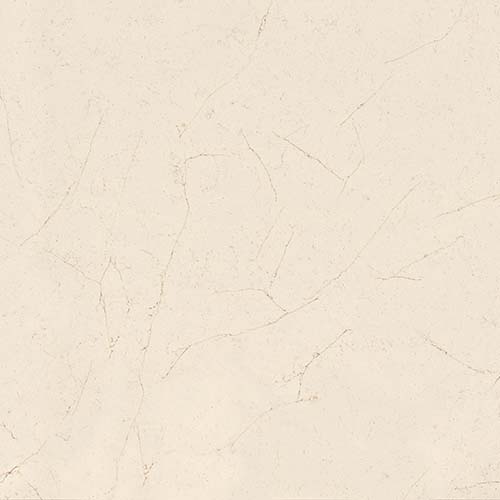

Some Silestone® colours have horizontal veining. Veins may vary in intensity and highlight seams. Base colour remains consistent between slabs. Veins when joined together may show and that the pattern can vary in intensity and also directional.

Tolerance

Tolerance in Silestone® Quartz is ±2mm

Thermal expansion

Due to thermal expansion Silestone® Quartz can expand up to 1mm per metre. A gap of at least 3mm should be left at each end of the worktop when fitted and filled with decorators caulk. When Silestone® Quartz is joined to other materials (such as glass, steel or wood) an elastic type of adhesive, for example polyurethane, is required for expansion.

Overhangs and supports

Any overhang extending more than 300mm must be supported.

Hob & Sink cutouts

- A minimum of 120mm is required between two hob cutouts.

- A minimum of 100mm is required between hob and sink cutouts.

- A minimum of 50mm is required between two sink cutouts.

- Sink cutouts are placed a minimum 50mm from the worktop front edge.

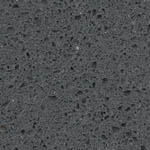

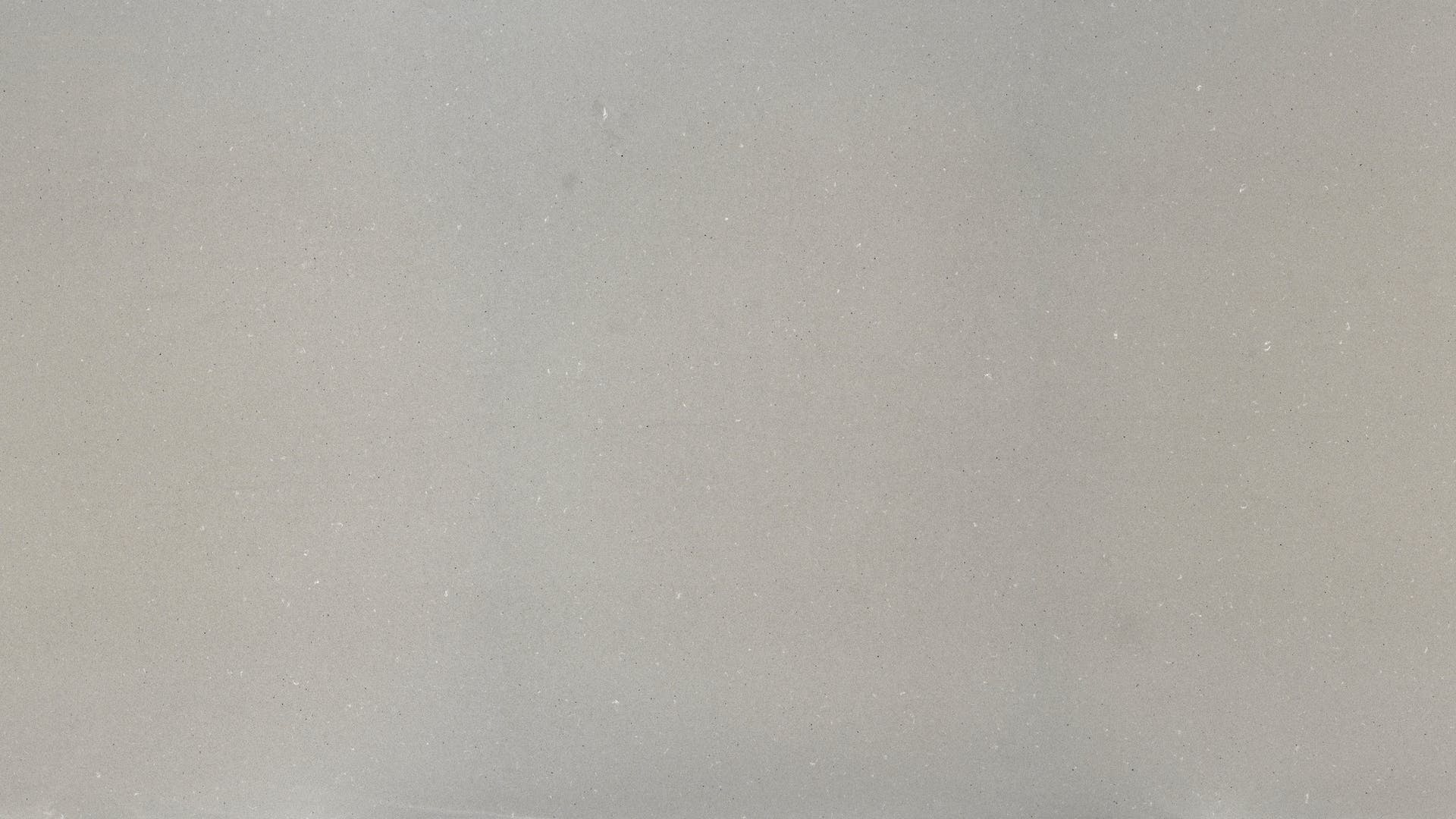

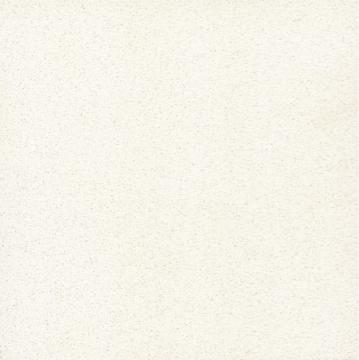

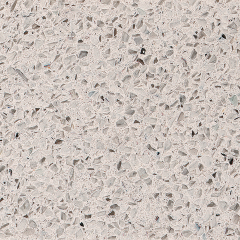

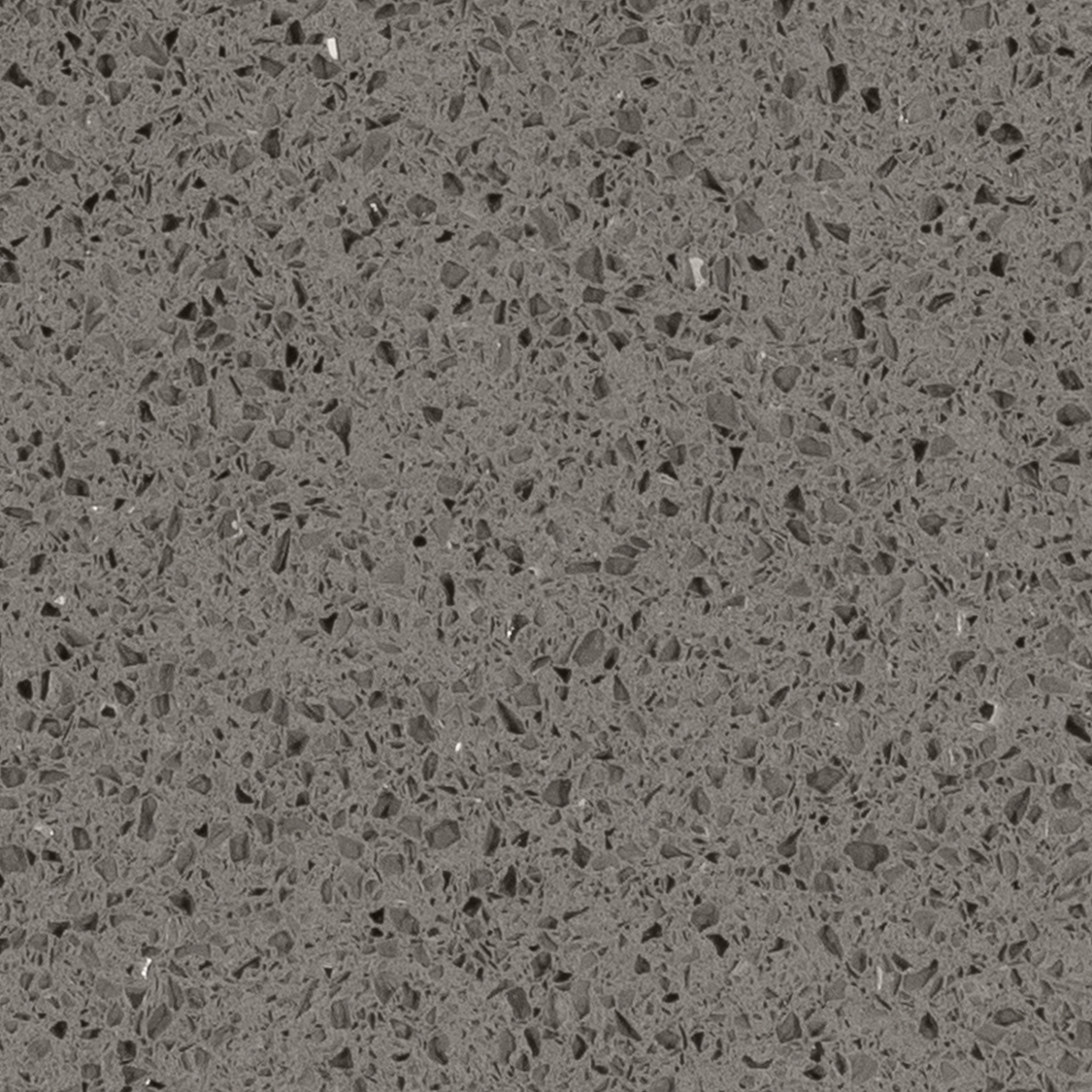

Samples

Samples can be posted out. Silestone Quartz is made in batches and the shade in colour may vary from the sample.